|

KMG Grinder Jigs and Attachments

|

|

Integral Grinding Attachment

The platen is Ό x

3 x 12 that has been cut down at the end that fits into the

small wheel fork. The end that fits between the fork is 2

Ό x 2. That area has been milled down on the back side

to a thickness of 3/16 to allow it to match the top radius of

the ½ wheel. You will also have to file out the corners

of the small wheel fork slightly, so the platen can fit

properly.

The angle iron riser piece is 2 x 2 angle iron. My

riser is welded about 1 3/8 from the end of the platen.

That is the distance (on my machine) that positions the platen

to fit under the belt. You want the belt to lie smoothly

on the top of the platen, so position your riser to lift the

belt slightly as it runs over the top end of the platen.

The base plate is Ό x 3 x 5 with two 1 long slots milled

into it for the attaching bolts. I drilled and tapped two

Ό x 20 holes in the top of the small wheel fork to attach the

platen.

To attach the platen to the machine; slide it onto the attaching

bolts and move it into a position that matches the top of the

wheel (I use a straight edge to check) then tighten it down.

|

|

|

|

|

Clip Grinding Attachment

The work plate on the clip grinding attachment is 4 X 20 X Ό steel. The brackets

are made from 3 X 3 X Ό angle iron. The arm to attach it to

the KMG is 1 ½ X ½ X 10.

A 3/8 slot is milled in the arm that attaches the fixture to

the KMG. The fixture doesnt need a long range of motion, so

you only need to make two shorter slots centered over the

attaching bolt holes.

The angle iron brackets were clamped together and two holes were

drilled of the size required for tapping 3/8 X 16 thread holes.

The two holes in the bracket for the work plate were drilled out

to 3/8, and the holes in the bracket for the attachment arm

were tapped with 3/8 X 16 threads. The attachment arm

bracket was clamped in the vice on the milling machine and the

work plate

bracket was bolted to it through the pivot bolt hole. The bolt

between the two parts was left loose enough so the work plate

bracket could move. A 3/8 end mill was lowered into

the other hole in the work plate bracket, the mill turned on and a Crescent

wrench was used to crank the bracket into the end mill and cut

the curved slot for the adjustment bolt.

Bolt the attachment arm to the KMG. Assemble the brackets

and the work plate and hold them in place with C-clamps.

After squaring everything up, tack weld the parts together.

Take it off of the KMG and weld it together solidly. DO

NOT overdo the welds!!! This fixture does not take a lot

of pressure in use, so it doesnt need huge welds. The

long piece of steel that the work plate is made from will probably warp when you weld it. The

more you weld, the more it warps and it will have to be

straightened.

Once the attachment

is welded together, the

unit will need to be fitted to your machine by installing it in

front of your flat platen and marking it to saw and grind a

section out to fit around the flat platen. Install the

attachment to your grinder and make marks on the work plate, about an eighth of an

inch outside both edges of your flat platen; laying out vertical

lines about 2 1/4" apart.

Draw a horizontal

line between the two vertical lines, and about 3/4" below the

top of the work plate. Saw out this rectangle area.

Put the

attachment on the grinder and set the angle of the work plate to

about 10 degrees.

Loosen the

mounting bolts slightly, so you can slide the attachment. Start

the grinder and push the attachment into the running belt to

grind the back side of the work plate. This will relieve the

back of the plate so that when you use the attachment, the face

of the belt will be close to the front surface of the plate. Grind into the back of the plate until there is about an

1/16" lip left at the front.

Use a file to

clean out the corners of the relieved

area.

I have put

painter's tape over the work plate on my attachment to protect

the blade from scratching. Other materials could be used; and

may work better too. I've heard that it was possible to have

things ceramic coated. Ceramic coating is very hard and slick.

This may be a good option.

The sharp corners

at the back of the riccasso tend to dig into the painters tape

on the work plate. I have found that it helps to also put tape

on the back of the blade.

Install the

attachment to the grinder and set the angle that you wish to use

for grinding the blade clip. 20 degrees is often a good angle

to use for bowie knives.

To use the

attachment, hold the knife blade down against the surface of the

work plate at the riccasso. Raise the front of the blade up

into contact with the grinding belt.

|

|

|

Shop Jigs and Fixtures

|

|

This is the most used fixture in my shop.

It has been used for drilling precise vertical holes, holding

parts for milling and a multitude of other uses. It has

threaded holes for attaching clamps to hold parts and also

precisely placed holes to pin two folder handles to it for

milling.

This jig is made from two

pieces of precision ground bar stock. The two pieces are

bolted together and are made to set in the jaws of my milling

machine vice. The tops of the milling machine vice jaws

are surface ground flat and square with the top of the milling

machine table. This jig will set on top of the vice jaws

and provide a work surface that is square with the milling

machine table.

One of my uses for this jig

is to drill pin holes through the handle material and tang of a

knife. The knife, with the handle glued on, is clamped to

the jig at the riccasso. A piece of wood is used with a

tapered wedge to support the handle so the pressure from the

drill doesn't cause it to flex downward. |

|

|

|

This is a set of tools that I made for

cutting a groove around an oval guard. They are made

of 3/8" micarta, cut to 7 3/4" long and 5/8" wide. An

1/8" slot is milled all the way through the micarta,

stopping a short distance from each end. Both ends of

the micarta piece have an 1/8" hole drilled into the slot.

A 1/8" chain saw file is inserted in one piece of micarta

and an 1/8" piece of drill rod is inserted into the other

micarta piece. The tool with the

file inserted, is slipped over the edge of the guard and

used to cut the groove. A piece of sandpaper is

wrapped around the drill rod in the other tool and used to

sand out the file marks. A bullet shaped Cratex point

is held in a pin vice and used to polish the bottom of the

groove. This tool makes it possible

to cut a perfectly centered groove around the guard and

easily finish the bottom of the groove. |

|

|

Hydraulic Press

Modifications and fixtures on a Riverside Machine

Shop hydraulic press.

|

|

Modification to a Riverside Machine Shop

hydraulic press. Five nuts are welded to a strip of steel. The

strip is welded to the press ram. By moving the bolt between the

nuts, the ram can be adjusted so that it does not return all of

the way to the top of the stroke.

This is a set of pattern dies, set up in a spring

loaded fixture. The bottom pattern die is fixed and the top die

sets on springs. With this fixture, a damascus knife blade's

bevels can be forged in, before pressing the blade with pattern

dies. This will give a cleaner damascus pattern from the blade's

spine, all the way out to the cutting edge. Washers are

placed around the fixture's guide pin on one side, to angle the

top die to match the forged in blade bevels. |

|

|

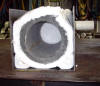

Propane Forges

The concept of my forge design, is to cast a forge body out of a tough

structural refractory. Then, insulate this forge body by wrapping it in

ceramic wool. This places the fragile ceramic wool on the outside of

the forge body, where it is protected and it also minimizes the

hazardous wool fibers from being blown into the air by the blast of the

forge blower. I have never had to rebuild my forges because of the

refractory being damaged in use.

|

|

|

|

|

|

Forge Front View

|

|

|

|

Forge Left Side Cut-Away

|

|

|

|

Forge Right Side Cut-Away

|

|

|

|

Forge Top View

|

|

|

These are sketches of the

cast forge body for a vertical forge. The casting is of Mizzou Plus refractory. The

body is 12 inches tall and 10 inches in diameter on the

outside. The interior is 8 inches in diameter. The forge body

walls are approximately 1 inch thick. The top and bottom

pieces of the forge are 1 inch thick plates of Mizzou Plus.

Mizzou mixes and casts just like concrete. Once

set, it is also as tough as concrete. So, no worries about

damaging your forge refractory from jabbing it with your work

piece. Also, Mizzou is not damaged by forge welding flux.

Mizzou is a structural refractory; not an insulating

refractory. When running the forge, the cast Mizzou forge body

will heat up to the operating temperature of the forge. The

ceramic wool overwrap, is what provides the insulation for this

forge design.

The forge body was cast

using cardboard forms for concrete piers. Door openings were

cut through both forms. Pieces of wood were cut from 2x6 boards

to block out the door openings. The wood blocks were inserted

through both forms during casting. This helps to stabilize the

forms and shape the door openings. When cutting the wood

blocks, put a slight taper on the edges of the blocks, towards

the interior of the forge. This helps with removal of the

blocks from the cured refractory.

The flame opening was formed

using a piece of 1 1/2 inch PVC pipe. The resulting flame

opening is 1 7/8 inches in diameter. The bottom of the flame

opening is 1 1/2 inches above the bottom of the forge. I cast a

4 1/2 inch tall, rectangular block around the flame opening for

additional strength. This may not be necessary.

Both forge door openings are

4 inches wide. The front door is 5 inches tall. The back

door is 4 inches tall. The bottom of the doors are 4 1/2 inches

above the bottom of the forge.

The cast forge body is

overwrapped with 1 inch thick, 8 pound Inswool.

|

|

|

|

|

|

|

|

|

Large Vertical Forge

|

|

|

|

Large Vertical Forge 2

|

|

|

|

Large Vertical Forge 3

|

|

|

|

Forge Stand

|

|

|

|

Forge Work Rest

|

|

|

|

|

|

Forge Work Rest Slider

|

|

|

|

Forge Work Rest Vice

|

|

|

|

Forge Doors

|

|

|

|

Forge Interior Bottom

|

|

|

|

Forge Interior Top

|

|

|

|

|

|

Forge at Welding Heat

|

|

|

I built steel casings for my current forges, but

this is not necessary for forges of this design. I put casings

on my forges, to make it possible to move them and to also make

it easy to mount doors on them. The only down-side to a cast

forge with no steel casing, is that it is difficult to move from

where it is placed and operated. The cast forge body will crack

during use, but it will not fall apart if it has a little

support. If you try to pick it up and move it, the cast forge

body may break into pieces.

This is my large, vertical propane forge.

The cast forge body in the section above, is used in this forge.

The cast forge body is wrapped in Inswool and inserted into this

steel casing. The square casing makes it easy to mount

doors and other accessories to the forge.

I mix a thin slurry of Satanite refractory and

paint it on the ceramic wool around the door openings.

This is to protect the wool from flux during forge welding and

also to prevent wool fibers from being blown into the air.

The doors are made of .050" sheet steel, with 1/2 inch Insboard linings. The doors hang on 3/8 inch rods,

allowing them to be positioned on adjustment brackets that are

welded to the forge casing. The adjustment brackets are

cut from 1 1/4 inch angle iron.

The adjustable work rest base is made of 2 pieces

of 1 inch angle iron, with spacers welded between them.

The sliding work rest can be adjusted for distance to the forge,

or removed from the base entirely. The sliding rest can

hold a variety of attachments, at adjustable heights. I

also have a drill press vice on a sliding mount, to use for

holding rods for twisting.

The forge stand is made of a "Shop Fox" brand

tool table and a "Shop Fox" mobile base. The table just

sets inside the mobile base. The wood table top is

overwrapped with sheet steel.

|

|

|

|

|

These are photos of the burner assemblies that I

build for use on my forges. The burner on the white

background is

made of 2 inch steel pipe, from the blower to the forge.

The nozzle is a pipe cap, with a hole drilled in it. The

gas inlet pipe is 1/4 in steel pipe. The gas pipe extends

about 1 inch into the elbow. There is no orifice on the

gas inlet pipe. A couple of these photos show the burner

assembly with a ball

valve for gas control. A ball valve works fine, but a needle valve

provides much more precise control of the gas flow. All of

the burners in my shop now have needle valves installed on them.

Air blast control, is by a sheet steel damper over the

intake of the blower.

These burners can be built with either larger, or

smaller pipe, depending on the size of the forge they will be

used on. The burner assembly mounted on a small forge, in

the above photo, is made of

1 1/4 inch pipe. This small burner assembly uses the same

size blower. The photo of this small burner shows a needle

valve for gas control. I have also changed my larger forge

burners to this same needle valve. A needle valve provides

much easier control of gas than does a ball valve.

Included is a line sketch of these burner

assemblies.

When mounting the burner assembly to the forge,

the pipe cap nozzle is not inserted into the body of the forge.

The nozzle just butts up against the side of the forge.

The blast is sufficient to blow the flame into the forge.

The size of the hole drilled in the pipe cap

nozzle, is determined by the size of the forge that the burner

assembly will be used on. The hole in the cap in the photo is 1 1/4" in diameter. This

cap is installed on a large burner assembly, that is used on a

forge that has about 600 cubic inches of interior

space. Start with a smaller hole size in the cap and try the forge

out to see how long it takes to come up to heat. If it

takes too long, increase the diameter of the hole until you have

enough blast to bring the forge up to temperature in a

reasonable amount of time.

The blower that I use on these burners is a unit

that puts out 146 cubic feet of air per minute. This

blower is a Dayton, Model #1TDP7. I bought this unit from

Grainger Industrial Supply. I added the sheet metal damper to

control the air volume through the blower. |

|

|

|

|

These are photos of the construction of my

horizontal forge. The construction methods for building

this horizontal forge are very similar to how the vertical forge

is made.

Concrete pier forms are used as inner and outer

molds for the forge body. I measure the forms by setting

them on a table and using a framing square to draw lines for

cutting. If making a vertical forge, the lines for cutting

out door openings are marked in the same way.

This horizontal forge body is 8 inches in outside

diameter and has a 6 inch diameter heating chamber. I have

recently found it difficult to find 8 inch and 6 inch diameter

concrete pier forms. So, I simply cut down larger pier

forms to create the needed smaller diameter forms for casting

the forges.

Measure the pier form and cut off any excess

material, leaving enough to create the desired diameter tube.

Leave about 2 inches to overlap and glue to create the smaller

diameter tube. Sand the edges of the tube for gluing.

I used 3M 90 spray contact adhesive for gluing the tube edges

together. After pressing the glued tube edges together, I

clamped the glued edge of the tube with a 2x4 and c-clamps.

A wood base is built for locating the bottoms of

the two pier tubes for casting the forge body. The form

for shaping the burner flame inlet is simply wired to the

outside of the outer pier tube. A wood support is attached

to carry the weight of the refractory. A piece of 1 1/2"

PVC pipe is used to form the flame inlet opening.

If using a steel casing around the forge body,

place the Inswool wrapped forge body into the casing before

welding the last piece of the casing in place. Only tack

weld the pieces of the steel casing. This makes it

possible to easily grind off the welds and open the casing, in

the event that the forge body needs replacement, or repair.

Or, if a piece of the casing needs to be replaced because of

oxidation damage from use.

|

|

|

Home

Gallery

Available

Pieces

Shop Gallery

Tutorials

Contact Info

Links Page

|